Understanding and preventing welding defects is crucial not only for the durability of your welds but also for safety.

Weld defects can weaken joints, leading to the potential failure of the entire weldment. In extreme cases, this leads to severe consequences.

So, whether you’re a seasoned professional or a beginner, it’s vital to recognize various types of weld defects and, more importantly, know how to prevent them.

With that in mind, let’s dive in.

What Is A Weld Defect?

A weld defect is an imperfection that weakens a joint and compromises its intended function, often leading to weld failure or rejection.

Weld defects can affect not only the structural integrity but also the aesthetics of your work. Some defects might not make the weld fail but can leave it looking sloppy and unprofessional.

The International Organization for Standardization (ISO) has set the industry standards for classifying these defects, detailed in ISO 6520.

But it’s worth noting that not all imperfections in a weld are classified as defects.

According to ISO 5817 and ISO 10042, a weld can have discontinuities and still pass inspection, provided they don’t exceed certain limits.

When the number of discontinuities surpasses these set limits, they become officially classified as defects, resulting in the rejection of the weld.

Weld defects are classified into two categories: internal defects and external defects.

13 Common Weld Defects

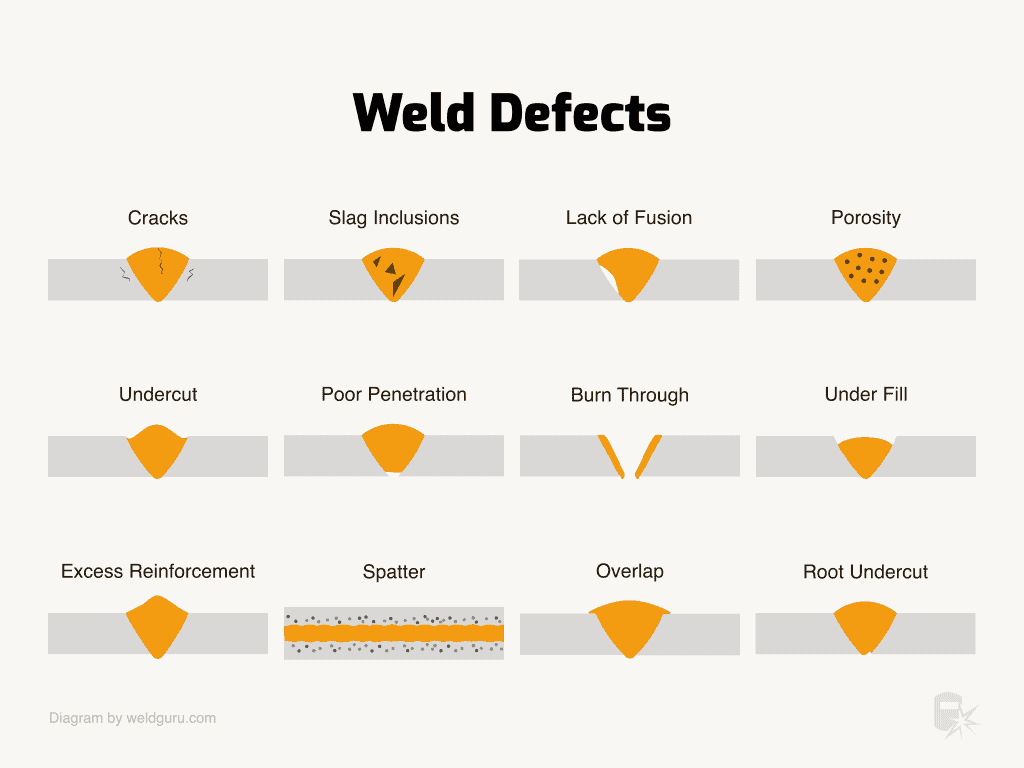

© weldguru.com – Image usage rights

There are many types of welding defects, but the most common ones are:

- Cracks

- Inclusions

- Lack of fusion

- Porosity

- Undercut

- Poor penetration

- Burn through

- Under-fill

- Excess reinforcement

- Spatter

- Over-roll/Overlap

- Whiskers

- Mechanical damage

It’s worth mentioning that irregular welds can also compromise the quality of your work.

Characteristics like being too wide or too narrow, having an excessively convex or concave surface, or displaying coarse, irregular ripples may stem from various factors.

These factors can include poor torch manipulation, incorrect speed of travel, or improper settings like arc voltage and stick-out, among others.

In the following sections, we’ll go into detail for each defect type and offer guidance on how to prevent or correct them.

1. Cracks

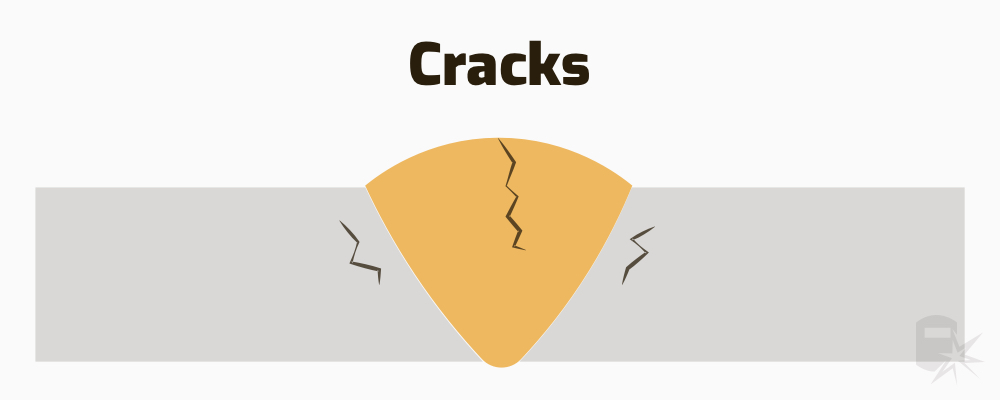

© weldguru.com – Image usage rights

Cracks are an internal weld defect and one of the most serious you can encounter, significantly weakening the integrity of a weld.

What makes them even more dangerous is their tendency to grow rapidly, worsening the issue over time. Therefore, understanding and preventing cracks is critical.

There are three main types of cracks:

- Longitudinal cracks – run parallel to the weld, weakening its entire length.

- Transverse cracks – traverse the width of a bead, causing localized but severe weaknesses.

- Crater cracks – often form star-shaped marks at the end of a weld when the arc is terminated

Welding cracks can happen at different temperatures falling in the category of:

- Hot cracks – form during the immediate cooling phase after welding. Usually caused by using the wrong alloy filler. They appear due to mismatched cooling rates between the filler and parent metal.

- Cold cracks – develop hours or days after the weld is complete, often in ferrous metals like steel. Usually caused by impurities in the base metal or residual stress within the weld.

How to Prevent Cracks

- Use the correct alloy filler material for the metal you’re welding.

- Steer clear of welding high sulfur and carbon steel.

- Always preheat and allow your joint to cool down slowly.

- Maintain a proper joint fill to avoid a convex bead.

- Use a sound, defect-free base metal.

- Avoid combining low currents with high travel speeds.

- Refrain from using hydrogen shielding gas with ferrous metals.

- Keep a proper depth-to-width ratio for your joint.

- Take steps to eliminate craters at weld termination points.

- Account for expansion and contraction during both the welding and cooling process.

You can read more about weld cracks here.

2. Slag Inclusions

© weldguru.com – Image usage rights

Slag inclusions are internal weld defects where impurities become trapped inside a weld, significantly compromising its strength. While they commonly occur in flux-related processes, MIG and TIG welding aren’t immune either.

Understanding how to prevent these inclusions is essential for any welder.

- Flux-Related: Slag often forms in brazing, stick, flux-cored, and submerged arc welding. The slag needs to rise to the molten pool’s surface rather than getting trapped in the bead.

- MIG and TIG Welding: Contaminants such as bits of rust and even tungsten can lead to inclusions.

How to Prevent Slag Inclusions

- Clean the base metal thoroughly before welding.

- Avoid low amperage settings to prevent the weld pool from cooling too quickly.

- Maintain an appropriate torch speed to keep the welding and slag pools separate.

- Use the correct torch angle to promote a clean weld.

- Remove any slag from previous welds between passes.

3. Lack of Fusion

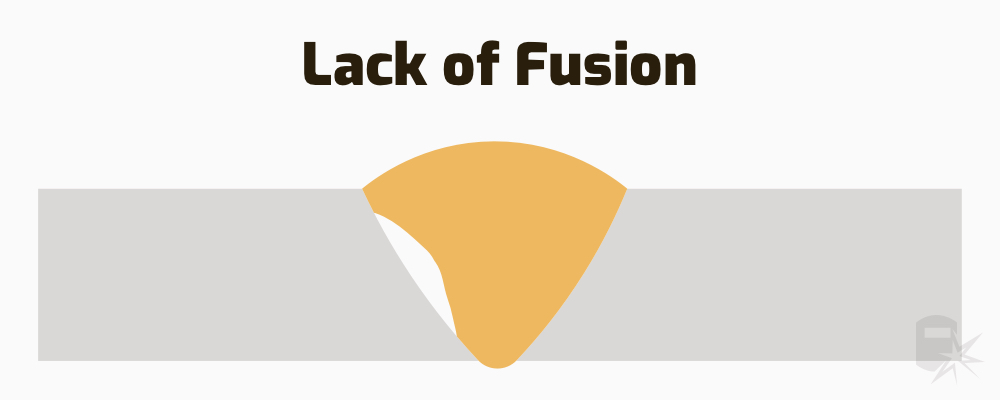

© weldguru.com – Image usage rights

A lack of fusion is an internal weld defect that occurs when the filler material doesn’t bond well with the base metal, leading to structural weaknesses like voids and gaps. Given the impact on structural integrity, understanding how to prevent this issue is vital for quality welding.

Understanding the Issue

A poorly bonded joint can result from improper technique, incorrect electrode size, or the wrong electrode alloy.

The weld’s structural integrity is compromised when there are gaps, voids, or poor adhesion between the filler material and the base metal.

How to Prevent Lack of Fusion

- Start by thoroughly cleaning the base metal to remove any impurities.

- Choose the correct electrode size and alloy to match the base metal.

- Maintain a steady torch speed; moving too fast can lead to gaps.

- Keep the arc length appropriate for the job at hand.

- Ensure your amperage setting is sufficient to create a strong bond.

4. Porosity

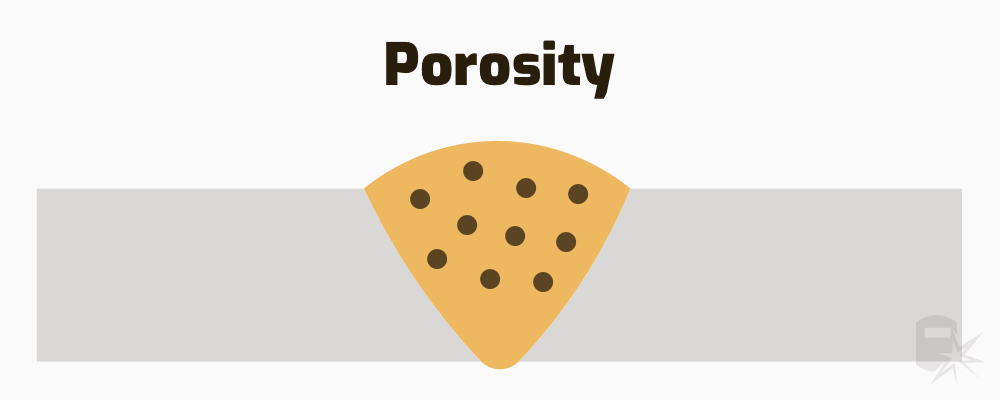

© weldguru.com – Image usage rights

Porosity in a weld, commonly known as “wormhole weld,” is an external weld defect that occurs when gas bubbles are trapped inside the weld bead, weakening the joint. These bubbles make the weld resemble a sponge, posing significant risks to the work’s durability.

Understanding Porosity

As you weld, gases like steam, hydrogen, and carbon dioxide typically bubble out of the molten bead. However, when these gases get trapped, they can seriously weaken the weld.

How to Avoid Porous Welds

- Start by cleaning and preparing the base metal; ensure it’s dry.

- Set your shielding gas flow correctly to avoid low or high levels that can trap gases.

- Keep the amperage appropriate; excessively high settings can exacerbate the problem.

- Use the right electrode alloy suited for your welding task.

- If your electrode has a coating, ensure it’s undamaged.

- Maintain a slow and steady torch speed to allow the molten puddle to form, giving gases time to escape.

- Use a short arc length.

- Use low hydrogen electrodes when possible.

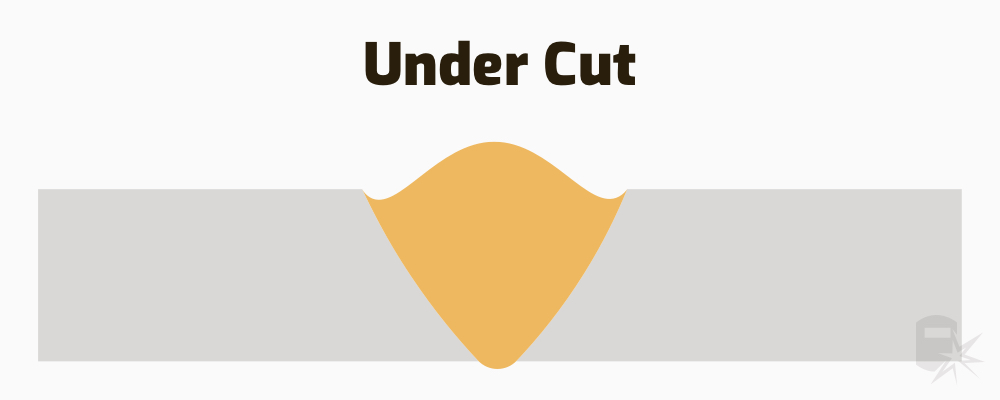

5. Undercut

© weldguru.com – Image usage rights

Undercut is an external welding defect where a groove or depression runs along the toe of the weld. It poses a significant risk to the structural integrity of the joint, making it more prone to cracks and failures.

Recognizing Undercut

An undercut typically appears as a “notch” on the edge of the weld and is often the result of excessive current or fast torch movement.

This defect leads to a loss in the material’s thickness, making the joint susceptible to fatigue and weakening the overall weldment.

How to Prevent Undercutting

- Maintain a steady and appropriate torch speed; moving too quickly can exacerbate the problem.

- Use the right amperage setting; too high can lead to undercut.

- Hold the torch at the correct angle, directing the heat toward thicker areas when possible.

- Select a correctly sized electrode for the job.

- Keep a shorter arc length for more control.

- Ensure your shielding gas is set to the correct flow rate.

- Follow proper welding techniques, such as using multiple passes to fill the joint properly.

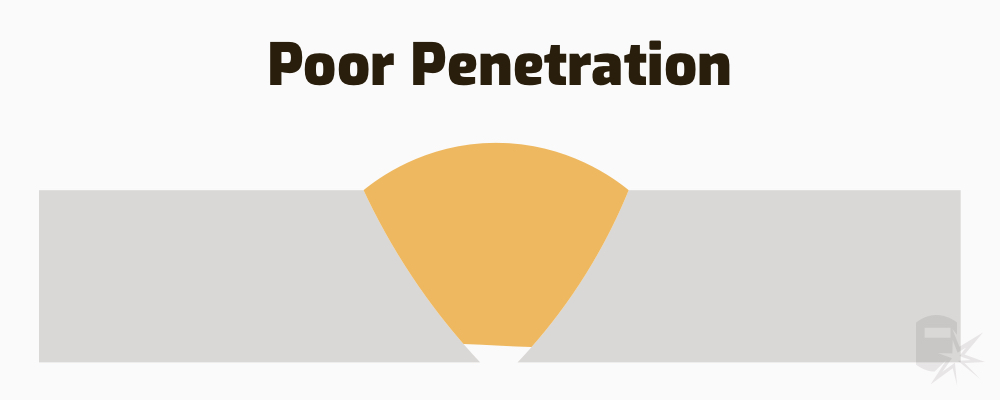

6. Poor Penetration

© weldguru.com – Image usage rights

Poor penetration, often called incomplete penetration, is an internal weld defect that occurs when the weld bead doesn’t fully penetrate the bottom of a butt joint. This defect seriously undermines the joint’s structural integrity.

Identifying Poor Penetration

If your weld bead isn’t filling the joint completely, you’re dealing with poor penetration.

This issue usually arises from incorrect electrode size, fast puddle movement, or improper joint preparation.

How to Achieve Good Penetration

- Choose the right size electrode; an oversized electrode will work against you.

- Don’t move the weld puddle too fast; slower movement ensures better penetration.

- Create V-grooves with 60 to 70-degree slopes for butt joints, aiding in proper penetration.

- Align your workpieces carefully to avoid large or irregular gaps, which can hinder proper penetration.

- Optimize your amperage setting; too low of a current can result in poor penetration.

- Minimize land thickness during your joint preparation to allow for better penetration.

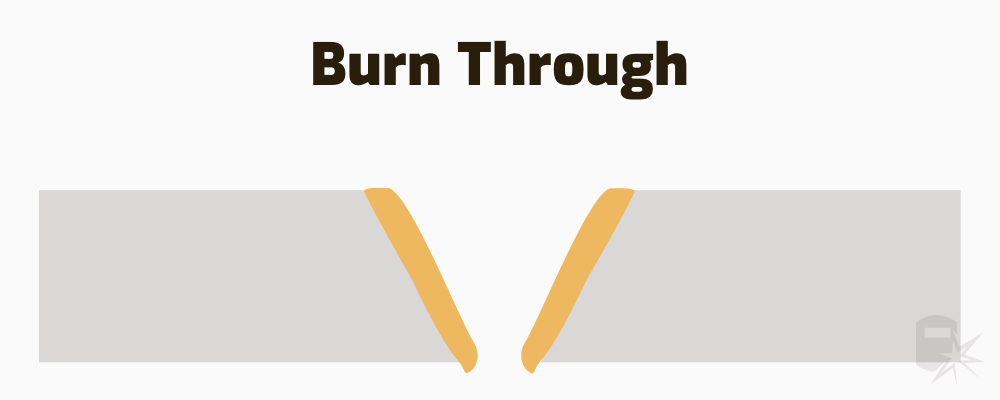

7. Burn Through

© weldguru.com – Image usage rights

Burn-through, sometimes called melt-through, is an external weld defect that occurs when excessive heat creates a hole in the metal, undermining the purpose of the weld and ruining the joint.

This defect is common when working with thin materials but can also happen with thicker ones if you’re not cautious with your settings and technique.

Identifying Burn-Through

Burn-through typically appears as an unintended hole in your material. It usually happens with thin stock less than 1/4-inch thick but can also occur in thicker materials if the welder settings are incorrect or the torch is moved too slowly.

How to Avoid Burn-Through

- Keep your welding current at a reasonable level to avoid excessive heat.

- Minimize gaps between plates that can cause heat to focus and result in burn-through.

- Maintain a suitable travel speed with the torch; moving too slowly increases the risk.

- Limit the bevel angle to reduce the exposed surface area.

- Choose a nose of appropriate size; a too-small nose can exacerbate the issue.

- Use the correct wire size; going too small can worsen the problem.

- Fit up correctly using metal clamps or hold-down techniques to keep the material steady.

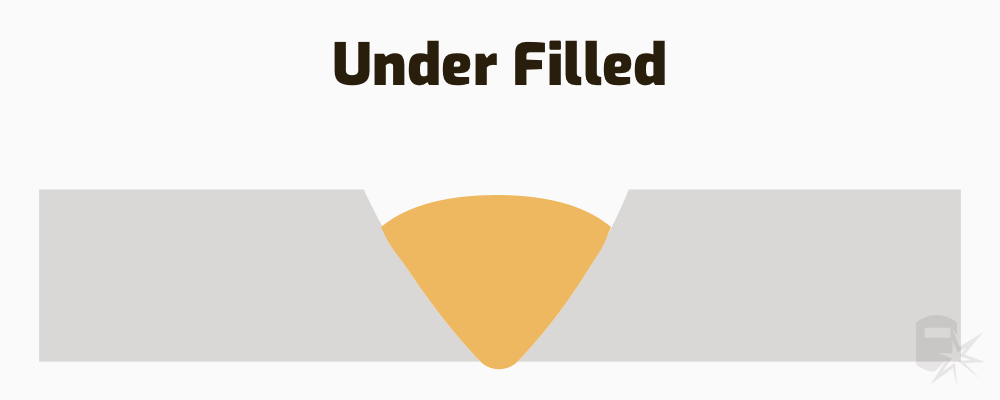

8. Under-Fill

© weldguru.com – Image usage rights

Under-fill is an external weld defect that occurs when the weld bead is recessed below the surface of the base metal, leading to a weakened joint.

This issue often appears as a longitudinal “rut” along the bead and may also be referred to as a convex joint.

How to Avoid Under-Fill

- Slow down your travel speed to allow the weld pool to fill in properly.

- Use the right current setting for adequate fusion.

- Choose the correct size for your electrode or filler wire.

- Make multiple passes to ensure the weld is filled to the proper level.

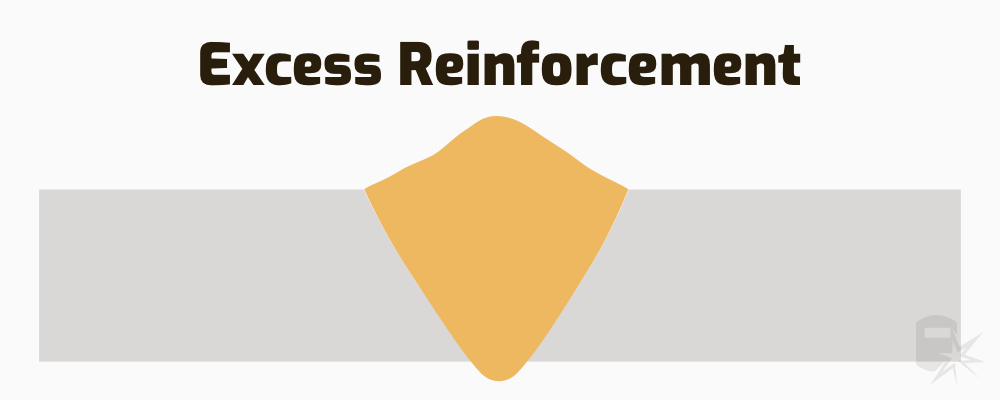

9. Excess Reinforcement

© weldguru.com – Image usage rights

Excess reinforcement is an external weld defect that occurs when there’s too much filler material in the weld, commonly referred to as a “high” crown.

Most project specifications and codes limit the height of such reinforcement, usually capping it at no more than 3 mm (⅛”) above the parent metal.

Variations of Excess Reinforcement

- Excess Penetration: When the filler material protrudes out from the bottom of the joint.

- Steep-Sided Beads: Caused by insufficient flux coating on the feed wire or low voltage settings.

- Mountain Range Reinforcement: This uneven, jagged form of excess reinforcement can result from excessive flux on the feed wire or inconsistent travel speed.

How to Prevent Excess Reinforcement

- Maintain an appropriate torch speed. Moving too slowly will lead to excessive filler, while too fast can result in an erratic bead.

- Correctly set your amperage to avoid excessive heat.

- Ensure your voltage is neither too low nor too high.

- Properly align the workpieces to avoid large gaps.

- Push the weld rather than dragging it to distribute the filler material more evenly.

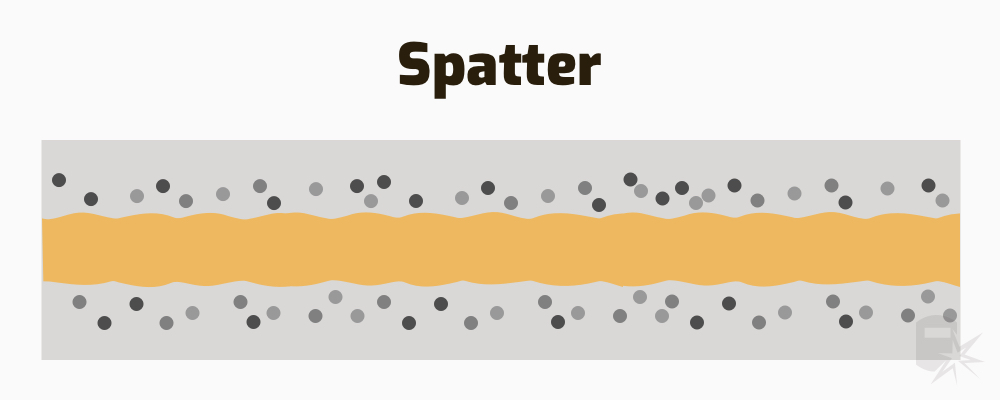

10. Spatter

© weldguru.com – Image usage rights

Spatter refers to the small droplets of molten material that scatter and stick to the surrounding metal during welding. Spatter can be classed as an external weld defect if it exceeds the amount specified.

Though generally not a threat to the weld’s structural integrity, spatter can detract from the visual quality of the finished work, affecting both its aesthetic appeal and perceived professionalism.

This issue is common in MIG welding but can also occur in other welding processes.

How to Minimize Spatter

While completely eliminating spatter may be difficult, you can take several steps to reduce its occurrence:

- Thoroughly clean the base metal before you start.

- Choose the correct amperage to avoid “hot” settings that contribute to spatter.

- Use the appropriate voltage; low settings can lead to more spatter.

- Make sure to set the polarity correctly for your welding process.

- Maintain a short arc to reduce the chance of spatter.

- Increase the electrode angle for better control.

- Check the feed wire to ensure it moves smoothly and is free of impediments.

Related: How to reduce weld spatter

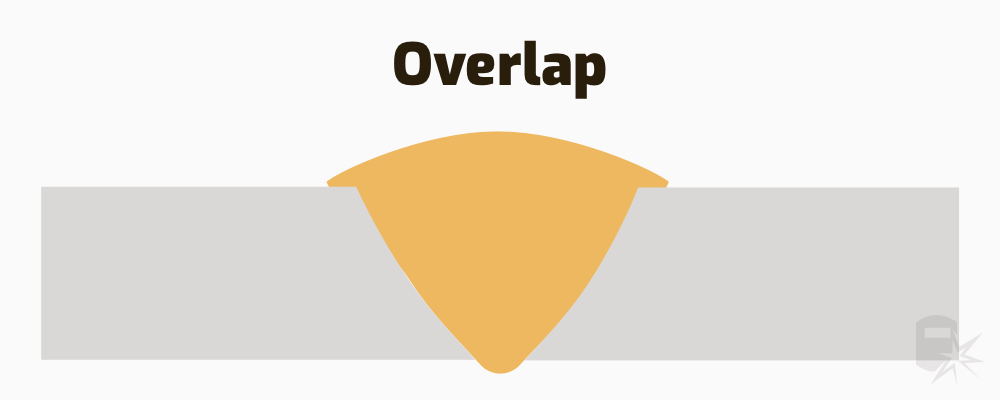

11. Over-Roll/Overlap

© weldguru.com – Image usage rights

Overlap, also known as over-roll or cold-roll, is an external welding defect that occurs when the filler material flows over the base metal but fails to fuse with it properly.

This condition typically leaves a roll of filler material at the weld’s toe, which can compromise the joint’s strength and appearance.

How to Prevent Overlap

- Avoid excessively slow travel speeds, which can cause filler material to build up without proper fusion.

- Maintain the correct torch angle to ensure better control over the molten pool.

- Refrain from using oversized electrodes, as this can contribute to the issue.

- Use the correct amperage settings; too high of a setting can lead to overlap.

12. Whiskers

Whiskers in MIG welding refer to short segments of the electrode wire that protrude from the root side of the welded joint.

These occur when the electrode wire is pushed beyond the leading edge of the molten weld pool.

Not only are these whiskers visually unappealing, but they also act as inclusions that weaken the structural integrity of the joint.

In piping systems, whiskers can obstruct fluid flow and may even break off, leading to equipment damage further down the line.

How to Prevent Whiskers

To avoid the formation of whiskers during your welding project, consider the following steps:

- Reduce your wire-feed speed to control the flow of the electrode wire better.

- Maintain an optimum travel speed; going too fast can result in whiskers.

- Increase the wire stick-out distance to provide a buffer against whisker formation.

- Utilize torch weaving techniques to distribute the heat and filler material more evenly.

13. Mechanical Damage

Mechanical damage refers to physical harm to a weld bead after welding is complete.

This type of defect can be caused by various tools such as chipping hammers, grinders, or even accidental impacts with other heavy objects.

Unlike other welding defects that occur during the welding process, mechanical damage often the result of post-weld handling or work environment conditions.

How to Prevent Mechanical Damage

- Be cautious when removing slag or cleaning a joint. Overly aggressive techniques can harm the weld bead.

- Avoid delivering heavy hammer blows to the weld, which can create deformities or cracks.

- Protect your weld from being impacted or ground over by other large pieces of metal, especially in busy work environments where multiple tasks are being carried out.

Wrapping It Up

Welding is as much an art as it is a science. The list of common defects we’ve reviewed is not exhaustive, but it underscores the importance of getting the basics right.

These aren’t just guidelines; they are the foundational elements that differentiate a strong, reliable weld from a defective one.

Key Takeaways

To recap, the cornerstones for quality welding include:

- Ensuring the base metal is clean and free from contaminants.

- Properly aligning the pieces, taking into account the type of weld and avoiding large gaps.

- Preparing V grooves at the appropriate angles when required.

- Correctly setting both amperage and voltage.

- Maintaining the right arc length.

- Keeping your consumable at the leading edge of your weld puddle.

- Moving the torch at an optimum speed.

- Using an appropriately sized electrode.

- Keeping your feed wire unobstructed.

- Finding and maintaining the right torch angle.

- Weaving the electrode skillfully when needed.

- Being vigilant against mechanical damage to both the parent metal and the finished bead.

By familiarizing yourself with these fundamental principles and how they can prevent various defects, you’re not just fixing errors—you’re elevating your craft.

Remember, nobody becomes a great welder overnight. Mastery comes from continual practice, and every mistake is an opportunity to learn and grow.

Keep honing your skills, and with time, you’ll find that what once seemed overwhelming becomes second nature.