You may be unaware of the hazard, but welding is among the highest-risk occupations for worker exposure to electromagnetic fields (EMFs).

EMFs are a form of non-ionizing radiation known to cause serious diseases and other harm to human health.

Moreover, research dating back nearly 70 years and more recent studies associate exposure to EMFs with leukemia and other cancers, sterility, heart disease, neurological conditions, memory loss, and blood sugar problems.

While the American Welding Society has said in the past, “Studies to date indicate that there is no confirmed evidence of health problems from EMF,” this is not the case.

For example, a 2005 investigation by Swedish researchers uncovered higher rates of endocrine cancer among welders.

In 2013, European welding companies were required to monitor worker exposure to EMF radiation and deploy counter-measures whenever exposure exceeds maximum safety limits.

This guide is designed to urge welders in the United States and elsewhere to learn more about this little-known threat.

What follows is a brief explanation of EMFs in a typical welding environment, a more general overview of wireless radiation, recommendations to help you protect yourself, and links to other websites for more information.

How EMFs Are Created

EMFs are present in all forms of welding where electricity is used.

In arc welding, for instance, high currents are generated by a power source flowing through a power cable into your torch and electrode, crossing the welding arc and entering the workpiece.

Generally speaking, the higher the current, the more intense the EMF.

Where the welder’s body is closest to the components in the circuit (machine, cables, torch, and work-piece), the higher the potential of harmful EMF radiation altering blood flow and causing a wide range of other symptoms, such as headaches, fatigue, skin rashes, and heart palpitations.

Your hands and arms, the area stretching from your torso to your thighs, and your genital organs are areas that receive the greatest exposure each time you weld.

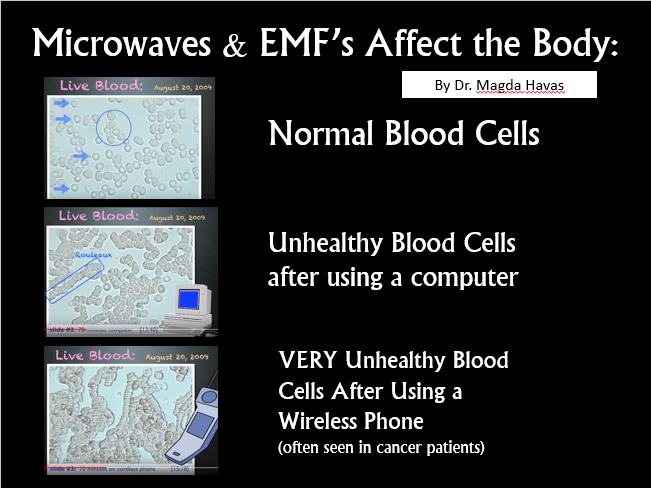

In the image below, a PowerPoint slide demonstrates how the magnetic force of EMF fields affects our iron-rich blood cells.

Notice that the cells appear to be forming lines, just like the filings. Graphics: Wikicommons, Dr. Magda Havas

Keep in mind that EMFs generated by high-frequency welding equipment and components, such as inverters and pulsed welding processes, may produce an additional type of EMF, known as radio-frequency (RF) radiation. RF energy radiates through space in the form of wireless waves or digital pulsing.

Imagine a “walls-of-Jericho” effect taking place within each of your 70 trillion cells, as these waves vibrate them constantly.

Biochemist Martin Pall has demonstrated how the membranes (walls) of cells leak calcium, disrupting the subtle bio-electrical pulsing that governs each cell’s function.

In response to requests from EMF safety advocates, Pall compiled a simple list of negative biological effects that can develop over time.

Non-welding power tools, especially grinding equipment, also expose welders to high levels of EMFs.

According to a 2001 survey by the National Institute for Occupational Health (NIOH) (NIOH), a handheld grinder produces 3000 milligauss (mg) of magnetism measured at the operator’s chest.

Most EMF researchers and safety advocates suggest that any sustained exposure higher than 10 mg be avoided.

However, cell pathology is thought to develop from daily accumulations taking place over months or even years so that short-term exposures by themselves are not considered hazardous by themselves. That’s because your immune system and detox defenses – as well as restorative activities like sleep – can reverse some or all of the damage, assuming you’re in good health.

In the survey mentioned above, the NIOH also found that welders incurred the highest daily median dose of EMFs (9.5 mg) of all occupations and the highest measured range of exposures (1.4 mg to 66.1 mg for 90% of the workforce).

Of course, EMFs aren’t restricted to the workplace. To the contrary, they’ve become commonplace in industrial countries since the invention of electricity, followed by high-tech electronics, especially mobile phones, cell towers, smart meters, weather radars, and numerous other wireless technologies.

The latter has created a phenomenon dubbed “electrosmog”, in which radiofrequency (RF) waves propagate through cities and residential neighborhoods 24/7/365.

The most common transmission frequency, 2.4 gigahertz, represents nearly two and a half billion waves flowing through the human body each second.

Curiously, this is the same frequency used by microwave ovens to agitate water molecules when heating food.

EMF Safety Regulations

While many initiatives are being considered by government agencies in the United States and most other countries, EMF exposures affecting welding and other occupational sectors have remained surprisingly unchecked.

However, in 2013 the European Parliament passed the Physical Agents Directive 2013/35/EU, which specifically targets exposure to EMF radiation in welding and other occupations.

Enforcement began in July of 2016 so that all European companies are now required to monitor exposure levels and develop mitigations where maximum limits (known as “action levels”) are exceeded.

In particular, a new software application called EMFWELD (www.emfweld.eu) has been developed to help implement the legislation.

After the user enters details of the equipment, welding parameters, and operator position for a proposed work assignment, the software calculates the EMF exposure based on a database of test case measurements.

A report is generated, providing interpretable maps of the magnetic field strength around the welding equipment.

This lets the user know what action is required to reduce exposure if it exceeds the established action levels.

The online software was developed by TWI, a UK-based company involved in welding and joining research.

Unfortunately, the exposure limits that determine the action levels are based on controversial standards issued by the International Community on Non-Ionising Radiation Protection (ICNIRP).

This group has come under intense scrutiny in recent years over its purported ties to the electronics industry.

EMF researchers and safety advocates contest the maximum limits, arguing that they’re at least a thousand times too high.

A coalition of EMF researchers known as the BioInitiative Working Group suggested a much lower set of maximum exposure limits in 2012. Still, those have yet to be officially recognized by most governments.

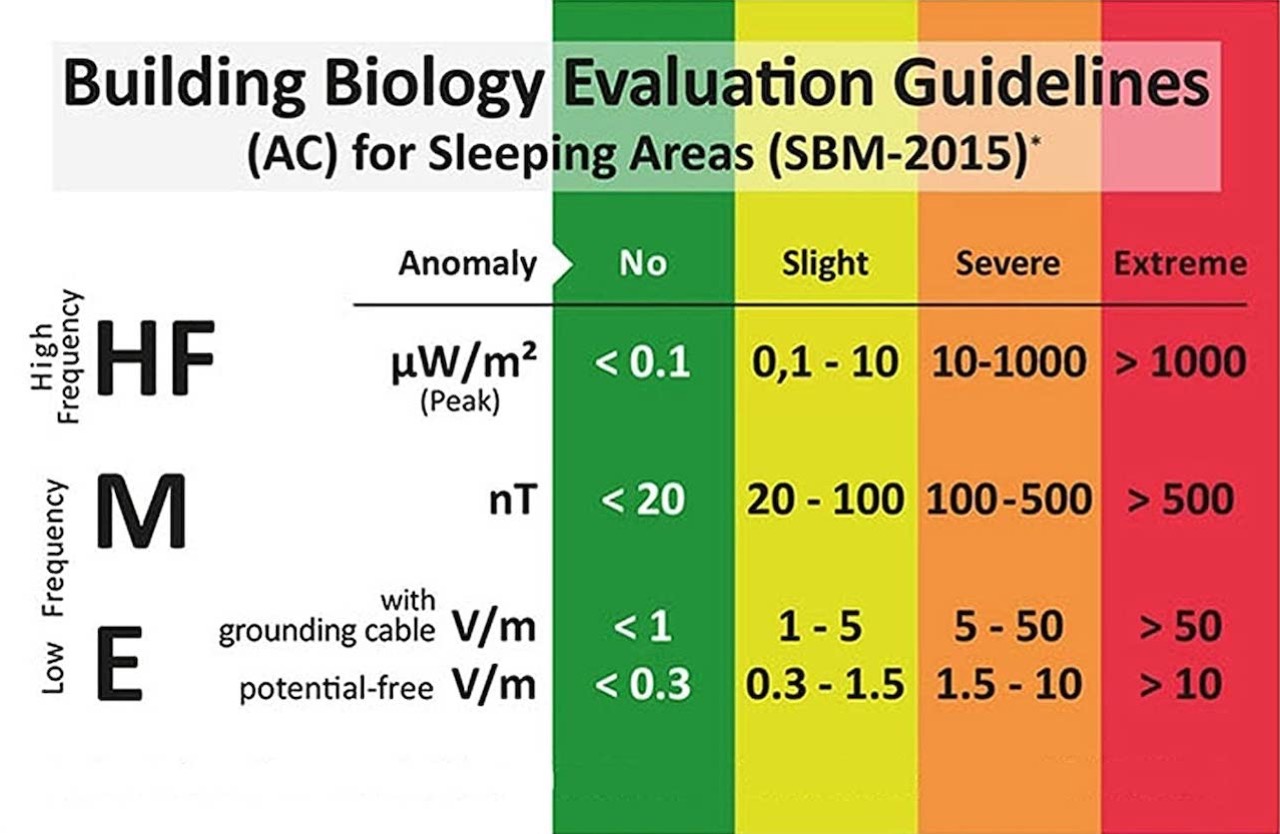

In 2015, the German-based Building Biology Institute set out its own limits based on the BWG recommendations, known as SBM 2015.

The institute oversees thousands of building inspectors worldwide who assist homeowners in making their homes safe to live in.

The EMF limits of SBM 2015 are summarized in the graphic below.

Preventing And Mitigating EMF Exposures

To measure your own exposure when welding, consider renting or purchasing a portable EMF or RF meter.

These hand-held devices measure radiofrequency (wireless) fields, magnetic fields, and/or electrical fields.

They can help you determine the intensity of RFs and EMFs at different distances from an EMF-emitting source like your welding machine.

As for taking counter-measures to limit your exposure, here are some suggestions listed by Lincoln Electric Canada:

- Route the electrode and work cables together. Secure them with tape or tie wraps when possible. If the cables are routed together, the EMF field at that point is reduced. Some cables even include electrodes and work conductors inside one cable, which may be a convenient way to reduce EMF exposure.

- Coiling the cables around your body increases your exposure to EMF. Do not place your body between the electrode and work cables. If the electrode cable is on your right side, the work cable should also be on your right side. There is an EMF field at and between each cable.

- Welding next to the welding power source increases your exposure to the EMF due to the field located at the welder.

- You may further minimize EMF exposure by using arc welding processes such as TIG or welding at the lowest DC output settings acceptable for your welding application. This is particularly important if you have a pacemaker or defibrillator.

- If you have a pacemaker or defibrillator and wish to continue to weld, you must talk to your physician and follow his advice. Your physician may want to contact the manufacturer of the pacemaker to obtain their recommendation about arc welding. In some cases, your physician may advise against continuing to weld.

You might also consider using electromagnetic shielding to help block or decrease the intensity of EMFs penetrating your body.

Numerous products are available nowadays, including clothing, underwear, hats, fabrics, foils, and specially designed metal alloys.